KB Series Excavator Pumps

Excavator pumps for tunnel construction and special civil engineering. Wherever the highest abrasive wear duties are expected, the metallic centrifugal pumps of types KB, KBK, KBH or KBKM is the right choice.

Characteristics

The compact pump model of KB series has been developed for challenging operating conditions in tunnel construction and special civil engineering with a rough operating environment and restricted installation conditions.

The compact design of our high-performance and highly wear-resistant pumps in the KB, KBK and KBKT model series are customised for use as a supply pump or a feed pump in conditions with limited space in micro tunnel construction and pipe jacking.

The extra thick walls of the pump in the KB series easily withstand the stress from sliding abrasion in case of fine solid particles, as well as the impact stress caused by a high content of coarse particles.

The pumps with pressure nozzles of DN 100, 125, 150 and 200 nominal size are available for diverse applications. Low installation heights, highly wear-resistant materials and shaft seals with an expeller, a so-called relief impeller, or our self-developed HGD mechanical seal ensure safe use and peak performance in micro-tunnelling AVN machines for automatic pipe jacking with slurry-circuit.

Main features of KB model series:

- Easy maintenance

- Easy adjustable suction gap

- Strongly dimensioned closed impellers, pump housing and wear plates

- Generously dimensioned extra thick walls providing extreme high impact resistance, as well as the best performance even with a high content of coarse particles in the pumping suspension.

Areas of Application

Sugar Industry

Animal waste, Beet pulp, Washing plants

Energy Management

Ash transport, Coal and coke processing, Condensate

Steel Industry

Blast furnaces, Hot rolling mills

Tunnel Construction and Civil Engineering

Civil engineering - diaphragm wall milling, Excavator works (ports, rivers), Micro-tunnel construction, Sand & gravel, Sand industry, Slate, marble, granite, Vertical bores (land and sea)

Processing & Mining

Coal/ ore / phosphates / potash/ bauxite, Fe, Zn, Cu, Ti, Salt, Al, etc., Flotation and foam medium, Heavy mining slurries, Iron oxide production, Mill discharge and separation, Ore slurries

Sand & Gravel

Extraction, Mineral processing, Water retention, Wet processing

Technical Specifications

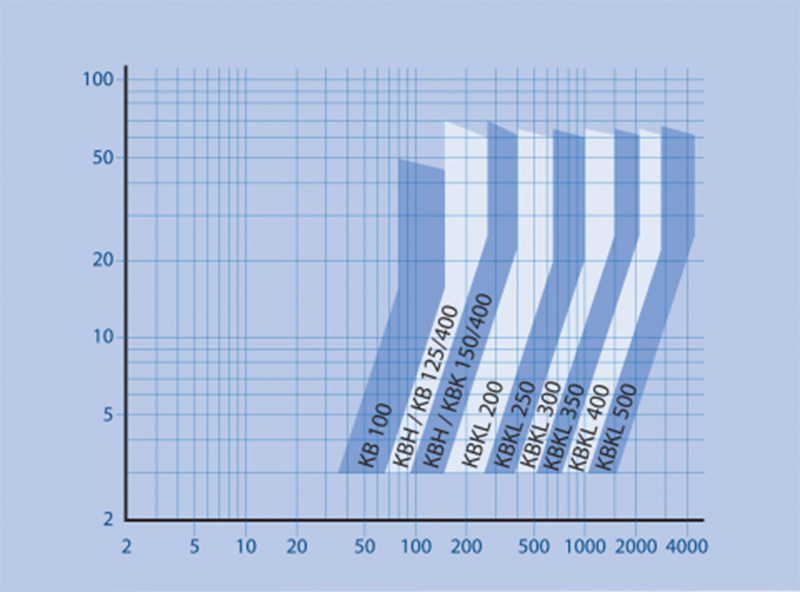

- FLOW RATEup to 50 - 5.000 m3/h

- DELIVERY HEAD, SINGLE-STAGEUP TO 85 M.FI.S

- PUMP SPEEDUP TO 2000 RPM

- CONNECTION SIZESDN100 - DN400

- MAXIMUM OPERATING PRESSURE10 BAR

- TEMPERATURE OF THE LIQUID100°C

- DISCHARGE NOZZLE POSITIONGRADUALLY

- CORROSION RESISTANCE AT PH3 - 14

Product Downloads

Click the links below to download product information

Make and Enquiry

For more information on this product please call us on NSW (02) 4271 2999 or QLD (07) 4952 3612 or fill out the form below and we will get back to you.