NPW Series Industrial Sludge Pumps

Ideal for industrial slurry handling. The main areas of application for the metallic centrifugal pumps of the NPW series are applications with light to medium wear. By using selected material qualities, this type can also be used with slightly corrosive/abrasive media.

Characteristics

This series is a single-stage centrifugal pump made of high-strength cast steel with easily replaceable wear parts and the option of adjusting the suction gap.

Impeller, wear plates and housing are dimensioned according to the requirements and optimized to achieve the best possible service life. Even under the toughest operating conditions, the NPW series achieves the lowest life cycle costs.

The single-stage centrifugal pump series NPW has wear parts that are easy to replace. The wear plates and the housing are braced via the two housing covers by means of tie rods.

The NPW pump series is a cost-effective pump for conveying slightly abrasive media and is used as:

- Drainage pump in quarries

- Feed pump in tunnel construction

- Mixer pump in the ready-mixed concrete industry

Your advantages:

- Material qualities optimized for your application for low life cycle costs

- Inexpensive pump variant for tough applications

Areas of Application

Chemical Industry

Aggressive chemicals, Fertilisers, PO4, Foaming suspensions, Pigments, Residues from crude oil, Sediments, soda, Separation, SO4, chloride, Waste recycling

Sugar Industry

Animal waste, Beet pulp, Biogas, fertiliser, Organic slurries, Wastewater treatment plants

Energy Management

Ash transport, Coal and coke processing

Tunnel Construction and Civil Engineering

Bentonite, cement batching, Chalk slurries, Excavator works (ports, rivers), Kaolin, clay, Micro-tunnel construction, Sand & gravel, Sand industry, Slate, marble, granite, Transport concrete, Vertical bores (land and sea)

Steel Industry

Blast furnaces, Sinter and scale deposits

Processing & Mining

Ceramic, glass cut-outs, Coal/ ore / phosphates / potash/ bauxite, Fe, Zn, Cu, Ti, Salt, Al, etc., Flotation and foam medium, Heavy mining slurries, Iron oxide production, Mill discharge and separation, Ore slurries, Slurry and sump pumps

Sand & Gravel

Mineral processing, Water retention, Wet processing

Technical Specifications

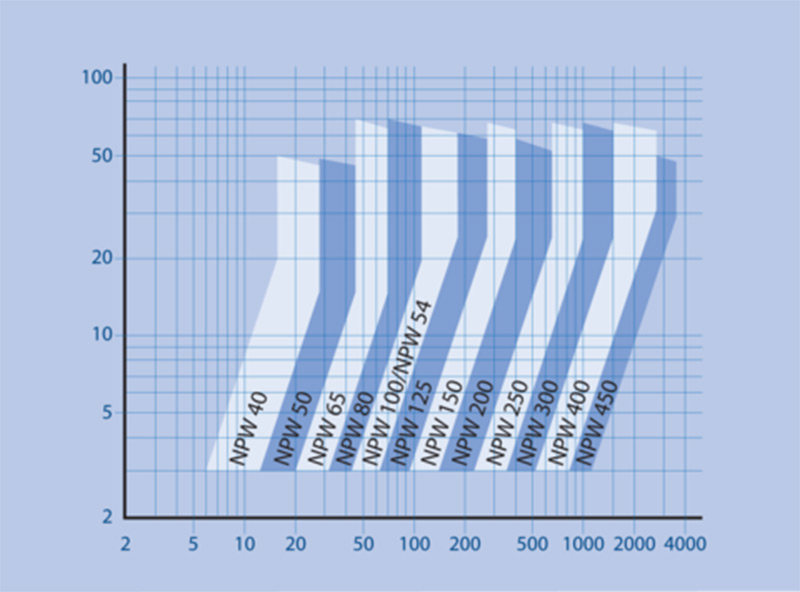

- FLOW RATEup to 4,600 m3 / h

- DELIVERY HEAD, SINGLE-STAGEUP TO 70 M.FI.S

- PUMP SPEEDUP TO 2,950 RPM

- CONNECTION SIZESDN40 - DN450

- MAXIMUM OPERATING PRESSURE6 BAR

- TEMPERATURE OF THE LIQUID90°C

- DISCHARGE NOZZLE POSITIONGRADUALLY

- CORROSION RESISTANCE AT PH3 - 14

Product Downloads

Click the links below to download product information

Make and Enquiry

For more information on this product please call us on NSW (02) 4271 2999 or QLD (07) 4952 3612 or fill out the form below and we will get back to you.